DIA

The DIA series is based on the latest FCD film material and requires only water and low-voltage direct current to rapidly produce superoxide water containing hydroxyl radicals and hydrogen peroxide. It effectively reduces pesticide residues and rapidly breaks down odours such as hydrogen sulphide, ammonia and methyl mercaptan. Superoxide water can also destroy the DNA and RNA of bacteria and viruses, quickly and effectively sterilise and disinfect, and produce carbon dioxide, water and oxygen.

Routine Disinfection & Elimination Area

It can be widely used in municipal, housekeeping, public environmental sanitation, animal husbandry, biological, medical and other fields.

Industry application

Medical facilities

Medical Dental Chair Water System

Medical Sterilisation Washers

Public facilities

Swimming Pool

Drinking Water Dispenser

Health Well-being Appliances

Water Purification System

Humidifier

Dishwasher

Washing Machine

Air Purifier

Prospects and Advantages of FCD Electrode Application

in the Disinfection & Elimination Market

Zero Pollution

Comparison of similar electro catalytic materials

Diamond carbon-based materials avoid heavy metal contamination, which is particularly important in the household appliance industry, and decompose quickly into water, oxygen and carbon dioxide after sterilization without producing any pollutants.

More Stable

Comparison of similar disinfection and elimination oxidation corona methods

Electro catalytic FCD avoids the problems of air corona method for oxygenated water, which involves nitrogen oxides, complicated process and unstable concentration of oxygenated water.

Lower Cost

Small size, low power, low cost

The excellent electrochemical window of diamond is the advantage of electrolytic release that cannot be achieved by similar products, which perfectly solves the problems of high cost and volume of electrocatalysis. For health well-being household appliances, the cost per litre of oxygenated water is only 1 cent per single statistic.

Higher Efficiency

Comparison of disinfection solutions

Using FCD diamond electrode as the core material, is the world’s first recognised oxidative ozone sterilization method, oxygenated water is ready to use without waiting, can be quickly and efficiently to the surface of the bacteria, organic bacteria and other harmful substances up to 99.99% removal, faster than the traditional method of time, as well as higher efficiency.

Leading a Great Health Life.

Campaigning Household Appliances with Disinfection & Elimination Function

DIA

Product Matrix

01

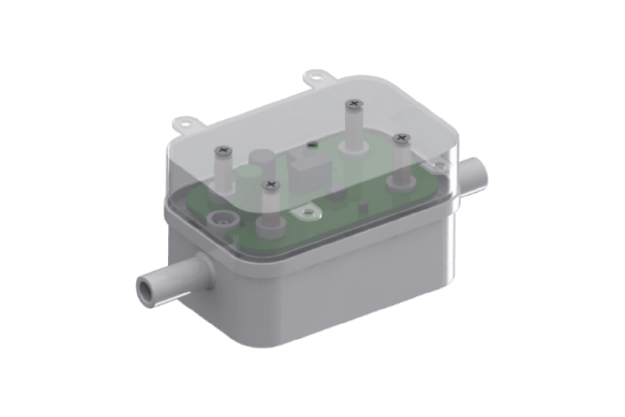

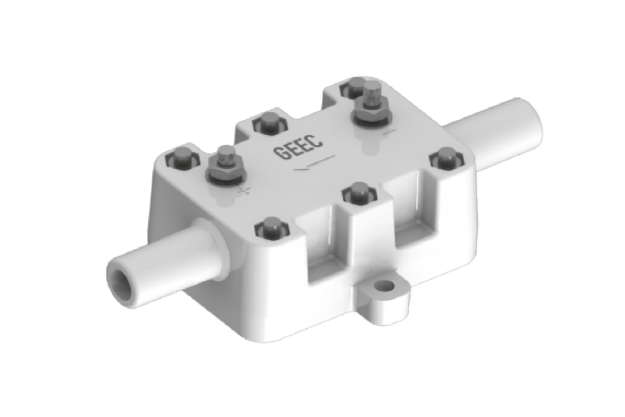

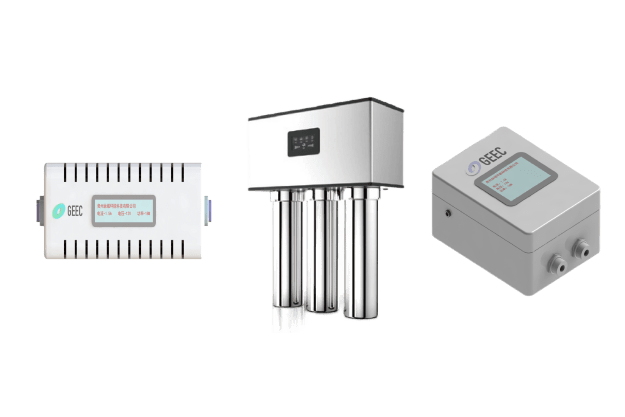

Function Test Modules #0

02

Customized Modules #1

03

Customized Modules + Electronic Controls

04

Customized Modules #2

05

Customized Applications #DF Series

Technical Highlights

Fast and efficient pesticide residue removal

A team of experts completed tens of thousands of sterilisation tests over a period of 18 months to come up with the optimal solution for pesticide residues.

Real-time monitoring of disinfection factor concentration

The first in China to develop a real-time monitoring of the concentration of disinfection factors, effectively controlling the time and effect of disinfection.

Applying multi-module design to solutions

Multi-module design ensures the realisation of customised solutions for a wide range of application scenarios, and it is also a clever solution to the problem of water pressure resistance in small volumes.

Precise adjustment of disinfection factor concentration

Test a variety of disinfection & elimination scenarios and accurately set the concentration of disinfection factors, water output and ozone overflow required for the elimination process. Meets the national health standard and the requirements for applying for D&E licence.